Chemical Innovation offer design solutions that meet industrial specific needs with technical expertise developing plastic additives, renewable polymer additive solutions that offer excellent technical performance. We combine proprietary technology with market insight to offer unique solutions for a variety of applications and processing methods.

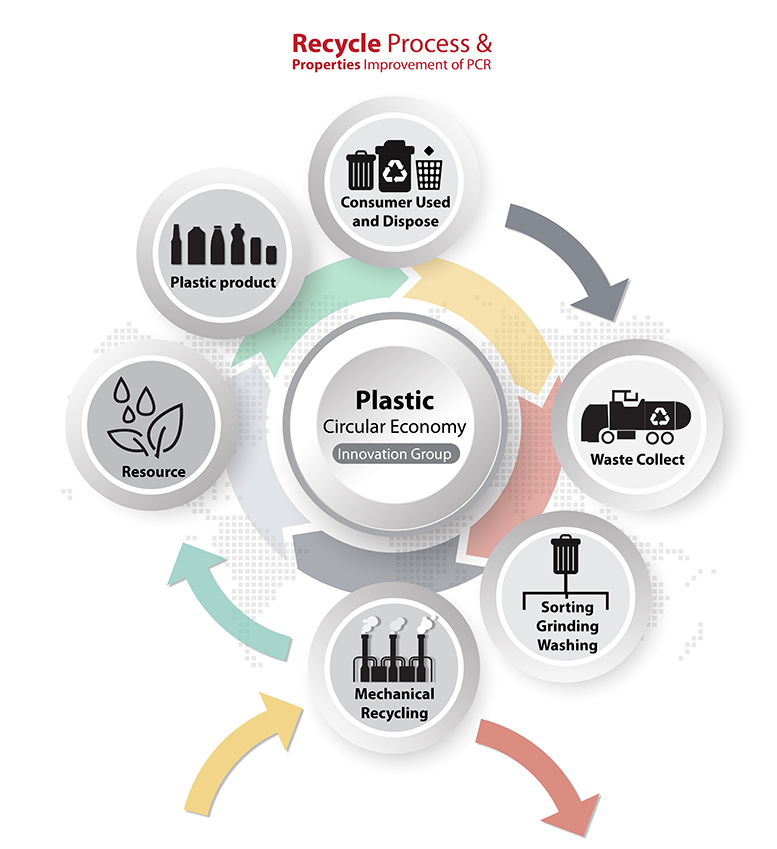

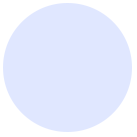

Plastic Recycling Solutions, our process starts with post-consumer waste. Then our team will design a solution to meet the application requirement or industrial specific needs, and then formulation and part design, prototype and application testing as well as compounding and pelletizing, while looking for opportunities to add value, improves quality and efficiency and manufacturing costs.

Additives Solution

Chemical Innovation is the additive solution distributor in Thailand for Bioplastics compound, Bio-based compound, and also value bale recycle plastic with various applications. We provide several of additives to solve pain point with improve the properties and performance Bioplastic and Recycle plastic application which can be classified in:

I: Bioplastic and Bioplastic compound

| Materials | Processing | Pain Point |

| PLA | – Extrusion and Thermoforming | – Hydrolysis and chain scission – Melt strength – Impact property |

| PBS | – Injection molding – Compounding | – Hydrolysis and chain scission – Melt strength |

| Blending PLA/PBS, PLA/PBAT | – Injection molding – Blown film extrusion | – CompatibilityHydrolysis and chain scission – Melt strength – Mechanical Properties |

| TPS/Bio-plastic (such as PLA, PBS, PBAT) | – Blown film extrusion – Injection molding | – Compatibility – Hydrolysis and chain scission – Melt strength – Mechanical Properties |

| Polyolefin/Bio-content (such as PLA, PBS, TPS, natural fiber) | – Extrusion – Injection molding | – Hydrolysis and chain scission – Compatibility |

Additive solution

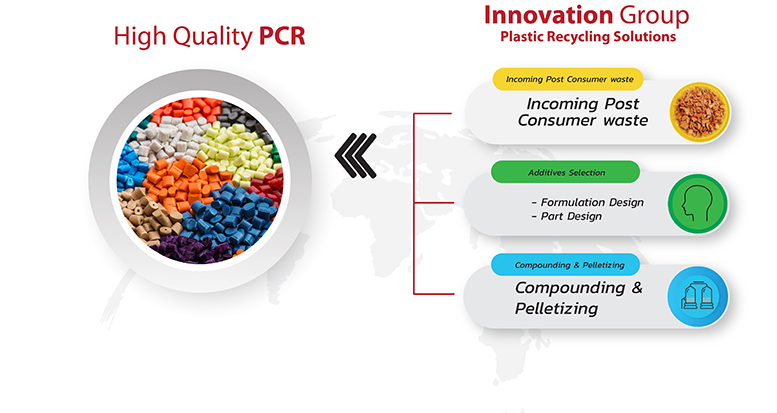

II: Post-Consumer Recycled (PCR)

Industrial recycle, post-consumer recycled (PCR) and valuable recycle, which can be classified in:

| Materials | Processing | Pain Point | Additive solution |

| HDPE | Extrusion Blow Molding – Bottle, Gallon | – Melt strength – Impact strength – ESCR | – Booster – Engage® – Versify® – Attane – Elvaloy® AC |

| PP/PE | Injection and Extrusion – Household product – Extrusion sheet | – Moisture conten – Need to dry before process – Silver streaks – Mechanical properties | – Elastoflex™ – MA65Engage® – Versify® – Elvaloy® AC |

| PET | Fiber spinning – Extrusion – Injection | – Increase intrinsic viscosity (IV) – Hydrolysis and chain scission – Impact strength | – Joncryl ADR – LUBIO – Chinox – Elvaloy® PTW |

| Nylon/Tie/ EVOH/LDPE | Extrusion – To be a new valuable product | – Compatibility – Mechanical Properties – Process ability | – Fusabond™ – Elvaloy® PTW – Elvaloy® AC |