Product Properties :

Active flow™ is a low molecular weight polyethylene homopolymer so it is compatible with polyolefin polymers. Acts as the melted viscosity reducer during polymer processing with no changes on physical or mechanical properties. It can improves the flowability, productivity, power consumption, and color dispersion. Active Flow™ is available in pastille form (round and flat) so it is easy to handle and mix with Polyolefin resin pellets.

Advantage of Active flow™ :

- No dust pollution.

- Low surface tension contributes to better color dispersion.

- FDA approval.

- Increased production rate

- Saving electrical energy

Applications :

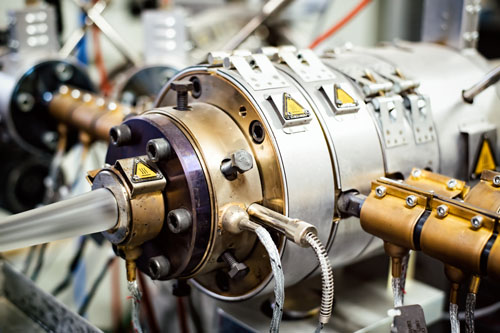

- Polyolefin polymers including extrusion and injection molding process.

Chemical name:

| Grade | Viscosity at 149 ° C, g/cm 3 | Density, g/cm 3 | Dropping point, ° C | Penetration index, d.mm | Recemmeded Application | Key Characteristic |

|---|---|---|---|---|---|---|

| Active Flow™ LP1040T | 15-40 | 0.94 | 116 | 2 | Film extrusion, Extrusion blow molding and Injection molding | Low viscosity, Good heat stability, Highly compatible with polyolefin, Improve flowability, Improve productivity, Improve color dispersion, Reduce precessing temperature, Easy to handle and mixing and FDA compliance |